Releases: prusa3d/Prusa-Firmware-Buddy

4.3.3 Firmware for Original Prusa MINI/MINI+

Summary

- Support for custom extruders

- Thermal regulation for custom extruders

- Extended print statistics

- Nozzle pressurizing improved

- Translations updated

- BSOD caused by a broken thermistor fixed

- Print timer fixed

This is the final release of firmware 4.3.3. This changelog is a summary of the previous release candidate 4.3.3-RC with additional changes introduced in this release. The main focus was to add features requested by the community, provide improved print statistics and fix certain bugs.

Compared to the previous release 4.3.2, there are 48 commits in 13 merge requests.

Support for custom extruders

We received requests from our community members to add configuration options for custom extruders. This release brings new functionality enabling the users to tune settings for a custom extruder on the MINI and MINI+. Previously, this was only possible with custom firmwares.

Installing a custom extruder is a significant change to the entire printer and might require multiple adjustments afterward. Therefore we recommend using this feature only in case you already have experience in this field.

To adjust settings for your custom extruder, go to LCD Menu -> Settings -> HW settings -> then long-press the knob. Similarly to the MK3S+, a new “Experimental” submenu will appear on the screen, where you can adjust the following:

- Save and return - while exiting this dialogue any adjusted value will be automatically saved

- Z-axis length - here you can adjust the length of the Z-axis based on your needs. In case you want to increase its length significantly, don't forget you might get limited by the cables.

- Default Z length - the system will fall back to its default value, which is 185 mm.

- Extruder steps per unit - different extruders might require different stepping

- Default steps per unit - the system will set the factory value, which is 325

- Extruder direction - there are two choices of spin, “Prusa” and the second is obviously “Wrong” 😉

- Default directions - set the direction back to the default (Prusa)

Once parameters are adjusted, click on “Save and return”, the printer will ask you whether you want to save the changes to the EEPROM and then restarts itself. When the printer boots up again, the changes are applied across the system. This was done to ensure that even with adjusted parameters the printer will be still able to perform First Layer Calibration, Live Adjust Z and, of course, print.

Thermal regulation for custom extruders

Due to the support of custom extruders, we received requests from the community to enable Marlin PID in the firmware. We have performed multiple tests using different materials to verify the “Prusa” thermal regulation works correctly on both stock and custom extruders. The results below show clearly that the current algorithm (a feed-forward driving + PID tuning of the steady state) is capable of correct thermal regulation in all tested scenarios including the sudden start of a cooling fan.

Test results for custom extruder:

Material: PLA

Temperature: target 215 °C, max 216 °C, min 213.9 °C

Material: ASA

Temperature: target 260 °C, max 263.1° C, min 258.9° C

Material: FLEX

Temperature: target 240 °C, max 241.6° C, min 238.4° C

Material: POLYCARBONATE

Temperature: target 275 °C, max 279° C, min 273.3° C

Also, the implementation of two regulating algorithms and switching between them creates a risk of a bug or failure, which can possibly lead to printer damage. Moreover, based on the results the default Marlin PID performs worse in some scenarios (e.g. when the cooling fan is suddenly started). Since the provided algorithm works as expected even for custom extruders, we have decided to keep it unchanged.

Extended print statistics (previously Odometer)

Another frequent request by our community is implemented in this firmware release. The printer now stores information not only about the filament used and print time but also about the distance traveled at each axis (X, Y, Z), which is displayed in meters.

For the final release, the developers have changed the name from Odometer to Statistics to match the terminology used in Prusa printers. Also, the graphics of this submenu were adjusted to fit the overall design of the user interface.

This feature opens the door for multiple features, some of them will be introduced in the upcoming releases. For example:

- Planned printer maintenance - once the bearings or other components reach a certain threshold, the printer will inform the user and provide instructions on how to clean, maintain or replace selected parts.

- Storing print statistics to a server - once the printer is connected to the upcoming Prusa Connect service, it will send the statistics and enable easier management of larger farms.

- Becoming a 3D printing grandmaster - the printer is capable of storing a print time of 9999 days 99 hours. The first user to reach this value on a final release without any tricks will become a grandmaster of 3D printing.

All print data is stored in the EEPROM. To optimize the number of writes to the memory, only finished or stopped prints are saved. In the case of a watchdog reset mid-print, the data is not stored.

Nozzle pressurizing improved

In some scenarios, after a filament change, the printer created a blob imprinted in the object. Removing this surface irregularity was hard once the filament solidified and for this reason, the developers have improved the algorithm responsible for the filament change. It is based on the one used in the MK3S+.

Once the proper filament change is confirmed by the user by selecting “Color correct”, the printer starts to pressurize the nozzle to achieve even filament distribution. This results in a thin string of filament being pushed out of the nozzle. It is necessary that the user removes this string with pliers or another tool before the nozzle reaches back to the printed object. It is important to note that the NOZZLE IS VERY HOT at this point, thus removing the string by fingers will inevitably result in burns.

This behavior is now used by default every time a filament change is triggered during the print by command M600. If the printer is stationary and load/unload/filament change is selected manually by the user, then the nozzle pressurizing is not activated.

Translations updated

Due to the new features introduced in this release, all languages were updated. The only exception is the experimental menu, which remains untranslated, as it includes advanced settings and requires the user to be proficient in English. This update also solves issue #1575.

BSOD caused by a broken thermistor fixed

The developers have identified an incorrect printer behavior in a situation when the print is run remotely using Octoprint and the thermistor either gets broken or is accidentally removed from the Buddy board.

Instead of properly displaying the red screen (THERMAL RUNAWAY/MINTEMP), the printer crashed to BSOD or the Watchdog reset screen. This is now fixed and this might also resolve other situations, where the printer is showing the Watchdog reset.

Print timer fixed

The developers have accidentally introduced a bug into the previous release 4.3.3-RC. In some scenarios the system didn't stop counting the elapsed time, even after the print was already finished. This is now fixed while printing from the USB flash drive.

Note that while printing over the serial line (e.g. Octoprint/Pronterface), the system does not run the timer at all as it is difficult to determine the exact start and finish of the print in general.

4.3.3-RC Firmware for Original Prusa MINI/MINI+

Summary

- Support for custom extruders

- Nozzle pressurizing improved

- Extended print statistics (Odometer)

- BSOD caused by a broken thermistor fixed

This is the first public release candidate of the upcoming firmware 4.3.3. Based on the request from the community, the developers are introducing several new features.

Compared to the previous release 4.3.2, there are 34 commits in 8 merge requests and a significant amount of testing time.

Support for custom extruders

Based on the requests from the community this firmware release enables users to install and tweak settings for a custom extruder on the MINI and MINI+. Previously this was only possible with custom firmware.

Installing a custom extruder is a significant change to the entire printer and might require multiple adjustments afterward. Therefore we recommend using this feature only in case you have some experience in this field.

To adjust settings for your custom extruder, go to LCD Menu -> Settings -> HW settings -> then long-press the knob. Similarly to a MK3S+ a new “Experimental” submenu will appear on the screen, where you can tweak the following:

- Save and return - while exiting this dialogue any adjusted value will be automatically saved

- Z-axis length - here you can adjust the length of Z-axis based on your needs. In case you want to increase its length significantly, don't forget you might get limited by the cables.

- Default Z length - the system will fall back to its default value, which is 185 mm.

- Extruder steps per unit - different extruders might require different stepping

- Default steps per unit - the system will set the factory value, which is 325

- Extruder direction - there are two choices of spin, “Prusa” and the second is obviously “Wrong” 😉

- Default directions - set the direction back to the default (Prusa)

Once parameters are adjusted, click on “Save and return”, the printer will ask you whether you want to save the changes to the EEPROM and then restarts itself. When the printer boots up again, the changes are applied across the system. This was done to ensure that even with adjusted parameters the printer will be still able to perform First Layer Calibration, Live Adjust Z and, of course, print.

Nozzle pressurizing improved

In some scenarios, after a filament change, the printer created a blob imprinted in the object. Removing this surface irregularity was hard once the filament solidified and for this reason, the developers have improved the algorithm responsible for the filament change. It is based on the one used in the MK3S+.

Once the proper filament change is confirmed by the user by selecting “Color correct”, the printer starts to pressurize the nozzle to achieve even filament distribution. This results in a thin string of filament being pushed out of the nozzle. It is necessary for the user to remove this string with pliers or another tool before the nozzle reaches back to the printed object. It is important to note that the NOZZLE IS VERY HOT at this point, thus removing the string by fingers will inevitably result in burns.

This behavior is now used by default every time a filament change is triggered during the print by command M600. If the printer is stationary and load/unload/filament change is selected manually by the user, then the nozzle pressurizing is not activated.

Extended print statistics (Odometer)

Another frequent request by our community is implemented in this firmware release. The printer now stores information not only about the filament used and print time but also about the distance traveled at each axis (X, Y, Z), which is displayed in meters.

This feature opens the door for multiple features, some of them will be introduced in the upcoming releases. For example:

- Planned printer maintenance - once the bearings or other components reach a certain threshold, the printer will inform the user and provide instructions on how to clean, maintain or replace selected parts.

- Storing print statistics to a server - once the printer will be connected to the upcoming Prusa Connect service it will send the statistics and enable easier management of larger farms.

- Becoming a 3D printing grandmaster - the printer is capable of storing a print time of 9999 days 99 hours. The first user to reach this value without any tricks will become a grandmaster of 3D printing.

All print data is stored in the EEPROM. To optimize the number of writes to the memory, only finished or stopped prints are saved. In the case of a watchdog reset mid-print, the data is not stored.

BSOD caused by a broken thermistor fixed

The developers have identified an incorrect printer behavior in a situation when the print is run remotely using Octoprint and the thermistor either gets broken or is accidentally removed from the Buddy board.

Instead of properly displaying the red screen (THERMAL RUNAWAY/MINTEMP), the printer crashes to BSOD or the Watchdog reset screen. This is now fixed and this might also resolve other situations, where the printer is showing the Watchdog reset.

4.3.2 Firmware for Original Prusa MINI/MINI+

Summary

- Upgraded USB drivers

- Upgraded Newlib library

- FatFs library upgrade

- Saving of self-test results

- Fixed bugs

This is the final release of firmware 4.3.2. This changelog is a summary of the previous releases (beta1, RC1 and RC2). The main focus is on bug fixes related to the USB Flash drivers and performance-related optimizations.

Upgraded USB drivers

We’re constantly updating and optimizing the MINI+ firmware to further improve its performance and reliability. In this release, the developers focused on the USB driver responsible for handling all the data transfers from the connected USB flash drive (e.g., mounting drives, reading G-codes, ...). We received several reports that certain USB drives weren't working properly.

Together with the chipset manufacturer (STM company), developers have tested and deployed a new version of the USB driver. As a result, the Buddy board should now be able to communicate even with the problematic USB drives. Previously, when the drive wasn't properly recognized by the printer, the only option was to reinsert it. This is not necessary anymore, the system will handle it on its own.

Note that these fixes do not address a scenario when certain USB drives are not correctly detected by the bootloader. For example, while attempting to flash a new firmware.

Upgraded Newlib library

This firmware release brings an important upgrade to the Newlib library. The standard library is replaced with a more optimized Newlib-nano version. Also, the standard “printf” family functions are replaced with a different implementation.

This change results in several improvements and memory savings. Compared to the previous firmware 4.3.1:

- 98 kB of FLASH memory is saved

- 4 kB of RAM is saved (3 kB on heap/static allocations, 1 kB on stack)

- makes the printf() family functions fully reentrant and thread-safe (the previous implementation did not allow formatting of floats in ISRs)

Multiple tests revealed no negative effects related to these changes in the MINI+ firmware project. The measurements of RAM usage were done with release builds with metrics enabled while printing.

FatFs library upgrade

This build brings an upgrade of the FatFs library, which is supposed to fix synchronization issues of accessing the file system.

FatFs library has been upgraded from R0.12c to the latest version of R0.14b. The most important change is the fix of synchronization issues related to accessing the FAT file system. Please see the release notes of the FatFs library for details, where the synchronization fix is also discussed.

This also fixed several reported situations of BSOD after the removal of the USB drive from the MINI and MINI+.

Moreover, to improve the quality of testing of the USB drivers and file system fixes, we designed an automated device that simulates various edge cases while inserting and/or removing a USB drive. The testing device helped us to verify that the fix works as expected.

Saving of self-test results

The upgrade of the FatFs library also brings back the possibility of saving results of self-tests onto the USB drive (if present), which has been removed in previous versions due to random file system-related problems.

If you intend to use this feature, make sure there is a USB flash drive (FAT32) connected to the printer before the self-test is performed. Once the test is finished, a log file is saved onto the flash drive. Examples of use are provided in the release notes for firmware 4.3.0-RC1

Fixed bugs

Filament runout during serial print

When the print has been previously initiated from the serial line (e.g., OctoPrint) and a filament runout occurred, the printer did not react accordingly and the Change filament (M600) sequence was not initiated. Now, this behavior is fixed and even when the print is initiated by the serial interface, the Filament runout initiates the local Change filament sequence on the printer.

Extra head movements after the print ends

In rare cases, when the printer finishes the print, the print head performs additional random movements (repeated mesh bed leveling, additional purge line, etc.). From the reports, it seemed that this bug first occurred in firmware 4.1.0.

The developers have identified the issue caused by a long comment line in the G-code file (generated by PrusaSlicer merging all custom codes into one comment line), which is longer than the expected 95 characters. The characters exceeding the number 95 in this line were incorrectly parsed - text starting with the 96th character has been analyzed as a part of actual G-Code. In some cases, it may have contained G-Code commands, which have been interpreted and executed. The analysis was complicated due to users adding different Custom codes.

All concerned cases issued in Github are fixed now:

#864

#733

4.3.2-RC2 Firmware for Original Prusa MINI/MINI+

Summary

- FatFs library upgrade

- Saving of self-test results

This is the second release candidate of the upcoming firmware 4.3.2. The current focus is on bug fixes related to the USB Flash drivers.

FatFs library upgrade

Compared to the previous release RC1, this build brings an upgrade of the FatFs library, which is supposed to fix synchronization issues of accessing the file system.

FatFs library has been upgraded from R0.12c to the latest version of R0.14b. The most important change is the fix of synchronization issues related to accessing the FAT file system. Please see the release notes of the FatFs library for details, where the synchronization fix is also discussed.

This also fixed several reported situations of BSOD after the removal of the USB drive from the MINI and MINI+.

Moreover, to improve the quality of testing of the USB drivers and file system fixes, we designed an automated device that simulates various edge cases while inserting and/or removing a USB drive. The testing device helped us to verify that the fix works as expected.

Please let us know if you still encounter problems with the USB drives.

Saving of self-test results

The upgrade of the FatFs library also brings back the possibility of saving results of self-tests onto the USB drive (if present), which has been removed in previous versions due to random file system-related problems.

4.3.2-RC1 Firmware for Original Prusa MINI/MINI+

Summary

- Upgraded Newlib library

- Upgraded USB drivers

- Fixed bugs

- Known errors

This is the first release candidate of the upcoming firmware 4.3.2 with new features and several bug fixes.

Upgraded Newlib library

This firmware release brings an important upgrade to the Newlib library. The standard library is replaced with a more optimized Newlib-nano version. Also, the standard “printf” family functions are replaced with a different implementation.

This change results in several improvements and memory savings. Compared to the previous firmware 4.3.1:

- 98 kB of FLASH memory is saved

- 4 kB of RAM is saved (3 kB on heap/static allocations, 1 kB on stack)

- makes the printf() family functions fully reentrant and thread-safe (the previous implementation did not allow formatting of floats in ISRs)

Multiple tests revealed no negative effects related to these changes in the MINI+ firmware project. The measurements of RAM usage were done with release builds with metrics enabled while printing.

Upgraded USB drivers

In cooperation with the manufacturer ST, the developers have implemented the latest USB drivers available for the chipset running on the Buddy board. This update should increase the system stability and resolve several issues. See the section “Fixed bugs” for more information.

Fixed bugs

USB flash drive detection fixed

In some cases, selected USB drives were not correctly detected by the firmware while the printer was booting up. Even if correctly connected to the USB port, the printer ignored their presence and the user was not able to access the data.

The only solution was to remove the drive and reinsert it back. This is now fixed thanks to the new USB stack. Note that this fix does not address a scenario when certain USB drives are not correctly detected by the bootloader.

USB drive malfunction fixed

The new USB stack also fixes issues with certain USB drives, which were malfunctioning in specific situations.

Pronterface causes BSOD on 4.3.2-beta1

During the testing of the firmware 4.3.2-beta1, the developers have identified a BSOD error when trying to connect host software (e.g. Pronterface, OctoPrint) to the printer via a serial Micro USB port. This failure is now corrected and successfully tested.

Filament runout during serial print

When the print has been previously initiated from the serial line (e.g., OctoPrint) and a filament runout occurred, the printer did not react accordingly and the Change filament (M600) sequence was not initiated. Now, this behavior is fixed and even when the print is initiated by the serial interface, the Filament runout initiates the local Change filament sequence on the printer.

Extra head movements after the print ends

In rare cases, when the printer finishes the print, the print head performs additional random movements (repeated mesh bed leveling, additional purge line, etc.). From the reports, it seemed that this bug first occurred in firmware 4.1.0.

The developers have identified the issue caused by a long comment line in the G-code file (generated by PrusaSlicer merging all custom codes into one comment line), which is longer than the expected 95 characters. The characters exceeding the number 95 in this line were incorrectly parsed - text starting with the 96th character has been analyzed as a part of actual G-Code. In some cases, it may have contained G-Code commands, which have been interpreted and executed. The analysis was complicated due to users adding different Custom codes.

All concerned cases issued in Github are fixed now:

#864

#733

Known errors

Random BSOD after removal/eject USB drive

In some very rare scenarios, a BSOD occurs while inserting/removing the USB flash drive. It is very difficult to replicate not knowing the all circumstances under which the issue has happened. We are still investigating and executing a deep root cause analysis. This issue is planned to be fixed before the final release of firmware 4.3.2.

4.3.2-beta1 Firmware for Original Prusa MINI/MINI+

Summary

- USB driver updated

This is an early development release of the upcoming firmware 4.3.2 dedicated to experienced users. This build passed internal testing, but it is important to note that some bugs might still be present.

USB driver updated

We’re constantly updating and optimizing the MINI+ firmware to further improve its performance and reliability. This time, the developers focused on the USB driver responsible for handling all the data transfers from the connected USB flash drive (e.g., reading G-codes). We received several reports that certain USB drives weren't working properly.

Together with the chipset manufacturer (STM company), developers have tested and deployed a new version of the USB driver. As a result, the Buddy board should now be able to communicate even with the problematic USB drives.

Should you still have issues with your USB drive, please report it in the Buddy Repository.

4.3.1 Firmware for Original Prusa MINI/MINI+

Summary

- X-axis error during Wizard fixed

- Safety timer not activated fixed

This is a bug fix release of the previous final version 4.3.0, where two bugs were discovered. There are no changes between firmware 4.3.1-RC1 released last week and this final release of firmware 4.3.1.

X-axis error during Wizard fixed

We have received a few user reports stating that in rare cases, the initial Wizard or XYZ calibration failed while performing the X-axis check. As a result, the print head with leveling sensor (M.I.N.D.A. / SuperPINDA) remained parked outside the heatbed perimeter and later, when performing Z-axis check, the leveling sensor was unable to trigger the heatbed.

This is now fixed. If the X-axis check fails, the user is informed and the test of the axes is canceled. In such a case please ensure that the print head can move freely along the entire X-axis length and make sure you are following the regular maintenance, see the Handbook for more information.

Safety timer not activated fixed

During internal testing, we have discovered that in some scenarios the Safety timer feature wasn't activated correctly and the printer kept the hotend temperature while waiting for the user to confirm a system dialogue. It is important to note, that the printer can still operate safely. This is now fixed and all scenarios were tested multiple times to ensure that the trigger of the Safety timer is correct.

4.3.1-RC1 Firmware for Original Prusa MINI/MINI+

Summary

- X-axis error during Wizard fixed

- Safety timer not activated fixed

This is a bug fix release of the previous version 4.3.0, where two bugs were discovered.

X-axis error during Wizard fixed

We have received a few user reports stating that in rare cases, the initial Wizard or XYZ calibration failed while performing the X-axis check. As a result, the print head with leveling sensor (M.I.N.D.A. / SuperPINDA) remained parked outside the heatbed perimeter and later, when performing Z-axis check, the leveling sensor was unable to trigger the heatbed.

This is now fixed. If the X-axis check fails, the user is informed and the test of the axes is canceled. In such a case please ensure that the print head can move freely along the entire X-axis length and make sure you are following the regular maintenance, see the Handbook for more information.

Safety timer not activated fixed

During internal testing, we have discovered that in some scenarios the Safety timer feature wasn't activated correctly and the printer kept the hotend temperature while waiting for the user to confirm a system dialogue. It is important to note, that the printer can still operate safely. This is now fixed and all scenarios were tested multiple times to ensure that the trigger of the Safety timer is correct.

4.3.0 Firmware for Original Prusa MINI/MINI+

Summary

- New graphics for Live adjust Z

- Added support for PVB material

- QR Error codes

- Print sheet profiles

- New fan management

- Improved selftest and wizard

- First layer calibration updated

- Improved filament change process

- Sound notification changes

- Improved localization management

- GUI and WUI (Web User Interface) refactoring

- Prusa Connect Local upgraded

- PID disabled during heater test

- Bug fixes

This is the final release of the firmware. This changelog is a summary of the previous releases (RC1 & RC2) with a few additional changes introduced in this release. Compared to the previous stable release 4.2.1 there are major changes to the code, user interface, new features, and multiple improvements across the entire firmware.

- Over 600 commits to the firmware

- 250 pull requests (4 from the community members)

We would like to thank users @ftrofin, @JeffersGlass, @cpinamtz and @carlin57 for their contribution to this release

New graphics for Live adjust Z

Adjusting the distance between the nozzle and the surface of the sheet is a crucial part of the calibration as it affects the quality of the first layer. In the past, it was difficult to further improve the process due to the screen limitation, but thanks to the color display on the MINI/MINI+ the system is now able to display more important information and make the calibration process easier.

The entire screen is now redesigned. On the left side, there is a scale of the vertical Z-axis with a range of 0 to -2 mm. The orange bar represents the currently set value. In the middle of the screen, there is a graphical representation of the nozzle, which moves up and down based on the input from the knob. Below the graphical representation, there is the exact Z-axis value of the nozzle and the arrows are showing to the user, whether the nozzle is moving up or down.

Added support for PVB material

In January 2021, we have introduced the latest addition to our Prusament family of filaments. PVB is great for printing design models because the material is very easy to post-process with isopropyl alcohol (IPA). Read more about PVB in this blog article.

The PVB is now integrated into the printer's menu and you can select it while preheating the printer or loading/unloading the filament. Default and recommended temperatures are 215 °C for the hotend and 75 °C for the heatbed.

QR Error codes

We always strive to improve the user experience and the QR Error codes are the next evolution step. Until now, if the printer experienced an error, a short description was displayed on the screen and the user had to open either the Handbook or search the Prusa knowledgebase for a solution.

With this firmware release, the printer will display more information: the name of the error followed by a brief description and a QR code. Take your phone, scan the code, and get immediately redirected to an article, which will in detail explain, what happened to your printer and how to fix the problem.

Each error code comes with a short URL containing a code. This is useful in case you can't scan the QR code. Open help.prusa3d.com, type in the error code (e.g. #12201), or use the displayed short link, and get access to the required article. Moreover, all the articles are translated into seven languages.

How is each code created? Let's use error #12201 again as an example. The code consists of five numbers with the following pattern: XXYZZ.

- XX -> ID of the printer based on the USB PID (for MINI/MINI+ it is “12”)

- Y -> the category of the error (2 is used for the temperature errors category)

- ZZ -> specific error code (01 is used for the heatbed heating failure)

More information about the types of printers, categories, and a full list of the error codes can be found in the following GitHub repository.

The URL link embedded in the QR code may contain an optional “device hash” (this can be enabled/disabled in the Settings). Including this information enables us to check, whether you are running the latest version of firmware and if not, we will inform you at the top of the article. The information provided in the URL is stored in our database to help us better understand, which errors are the most common and how many errors each printer experienced.

Example of the URL in the QR code: https://help.prusa3d.com/en/12201/OI6HB7H6/410

- en -> a language of the landing page with the article

- 12201 -> the unique error code sequence

- OI6HB7H6 -> device hash

- 410 -> firmware version in your 3D printer

An example of the error page with the printer running outdated firmware

The device hash cannot be used to recover anything sensitive like a serial number and isn’t used for anything else than the QR codes feature therefore there are absolutely no security concerns. This feature is turned ON by default. In case you don't want to use this enhanced feature, you can switch it off in the printer's menu by setting the “Device hash in QR” to OFF.

Once you turn it off, the QR code URL will contain only the following: https://help.prusa3d.com/en/12201/

Print sheet profiles

Just like the MK3S+, the MINI and MINI+ also have a magnetic heatbed, which holds a steel print sheet. However, due to the different thicknesses of various sheets (textured vs smooth PEI), each sheet requires individual First layer calibration. Starting with this release, we are adding a useful new feature, which will store the settings for up to 8 sheets. You can then easily switch between the sheets (profiles) and the printer will load the stored values.

There is a new section of the settings menu called “HW Setup”, which will allow you to individually “calibrate” each sheet and some other parameters (see below). To set up the individual sheet profiles, please head to the Settings -> HW Setup -> Steel Sheets

With each sheet profile, you can perform the following actions:

- Select -> confirms the selection of the sheet, which will then become the default

- First layer calibration -> takes you through the first layer calibration process. This calibration must be performed with each sheet you plan to use

- Reset -> sets the values back to the factory defaults

As soon as two or more profiles are configured, you will be able to quick-toggle between them directly from the Settings menu and the currently selected print sheet is also displayed on the main menu screen between the speed and selected material. Steel sheets without calibration are not displayed in the quick-toggle menu item. When upgrading the firmware to version 4.3.0, the existing Z offset value from First Layer Calibration is copied to the first steel sheet. This does not apply to the downgrading process and the printer’s Z-height offset must be recalibrated.

Compared to the MK3S+ implementation, this firmware does not currently support renaming the sheet profiles to a custom name. We will bring this feature in one of the upcoming releases - if you have any requests regarding this feature, let us know.

New fan management

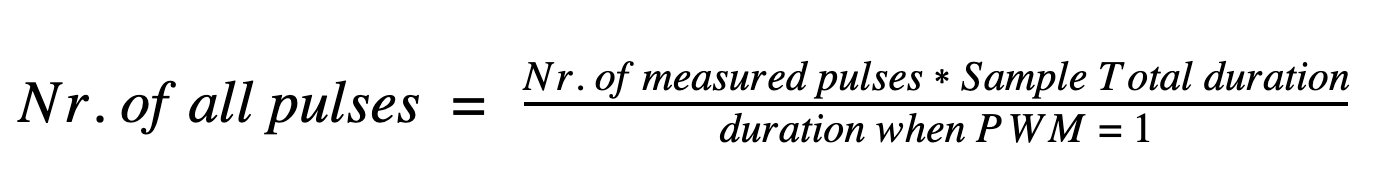

Improved RPM measurement for PWM-enabled fans

A new unique method was implemented to provide improved measurements and adjustments of the cooling fans’ RPM. This method enables to precisely control fans with 3 wires (power supply, ground, tachometer signal) even when the PWM (Pulse Width Modulation) is applied. In some scenarios, the PWM prevents the electronics from obtaining exact RPM data - this is now solved.

To explain this function a little further, the firmware is not using the standard method, where the fan was spun up to its maximum speed for a certain time period, to measure the RPM. The new method is more sophisticated, measuring the leading and trailing edges of the tachometer signal while the PWM is at value 1 (tachometer signal is not affected). The following formula is then applied:

Once the measurement is finished, the amount of impulses of the tachometer signal is converted to the RPM. A more detailed description of this algorithm will be available at our knowledge base site.

States of the fan

Keeping the fan spinning in lower RPM requires a small value of the PWM compared to the PWM needed to spin the fan up. The fan speed regulation is therefore split into multiple phases to ensure reliable performance in the entire RPM range. To spin the fan up, the printer is using phase “Start”, which is setting PWM temporarily at 100 % until the max speed and then sets the required RPM by lowering the value of the PWM.

Setting the RPM manually

The RPM of the fan is adjusted using a PWM factor, which can be changed in LCD Menu -> Settings->Temperature->Print Fan. In the current release, due to a historical reason (MK3) the firmware is displaying the direct PWM value (0-255), in the future release, this will be changed to the mor...

4.3.0-RC2 Firmware for Original Prusa MINI/MINI+

Summary

- Improved system dialogues

- Error screen includes appendix info

- RPM range increased

- PID disabled during heater test

- Saving logs to USB suspended

- Bug fixes

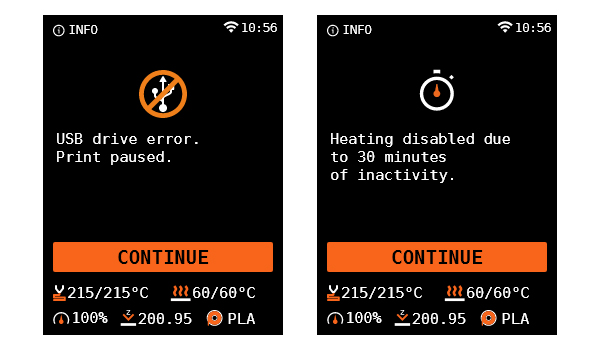

Improved system dialogues

Selected system dialogues were updated to improve clarity. In this release, new screens are introduced:

- USB drive error is detected during the print

- Heating is disabled after 30 minutes of inactivity

Error screen includes appendix info

In case of a more serious system error, a red error screen is displayed informing the user about what went wrong and how to fix it. Part of this screen is now information about the status of the appendix. There are two possible scenarios:

- The system detects the Appendix, then a [A] is displayed on the screen

- The system detects a broken Appendix, then no sign is displayed.

RPM range increased

Previously, the range of the cooling fans was set based on the measured values in the tests. However, as a result, some fans were not correctly evaluated by the system. The range will be thus temporarily extended and further adjusted after another round of testing to correctly detect and evaluate the connected fans.

PID disabled during heater test

While testing the hotend and heatbed heaters, the system now temporarily disables the PID regulating feature and uses full available power. This results in a faster heat-up, effectively shortening the test duration.

Saving log to USB suspended

The previous firmware release 4.3.0-RC1 enabled advanced users to save logs (results) of the tests to a USB drive for further evaluation. As stated in the release notes, this feature was experimental and in some scenarios may have caused a BSOD screen.

Based on the feedback, this feature is now temporarily disabled until a new, more robust, the USB driver is finalized by the developers. Applying a new driver will improve the handling of the USB flash drives and increase the overall stability of the system.

Bug fixes

- Some translated Prusa Connect Local messages were displayed with a longer delay, this is now fixed (response is faster).

- The final parking position of the print head (X-coordinate) was united for the First layer calibration and a finished print.

- In some scenarios, the testers were able to invoke a “watchdog reset”, but instead of displaying the red screen, the system showed a blue BSOD screen. There was an internal issue with the procedure “calling” for incorrect GUI function. This is now fixed.

- In case of damage to the thermistor (short circuit) on the hotend or heatbed, the system could end up in an endless loop of Maxtemp error screens. This scenario is now fixed and after the first reset, the system displays an error message and waits for user interaction.