using CAM files and a bit of manual prep we can generate a gcode file to run a laser to etch the component side of the board.

You can now use this to nest g-code (non-rotationally) to fill out a PCB

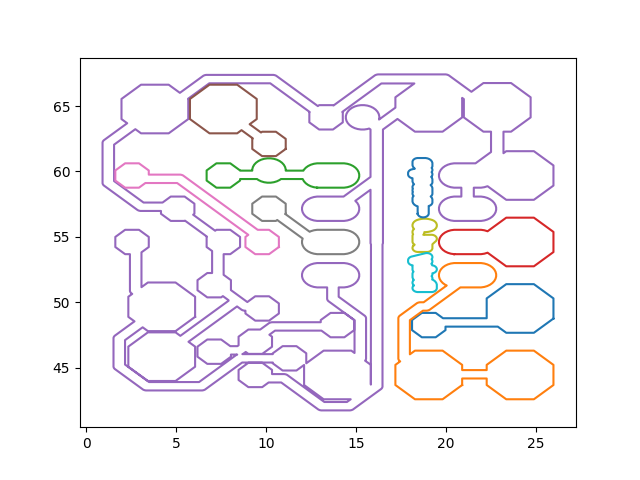

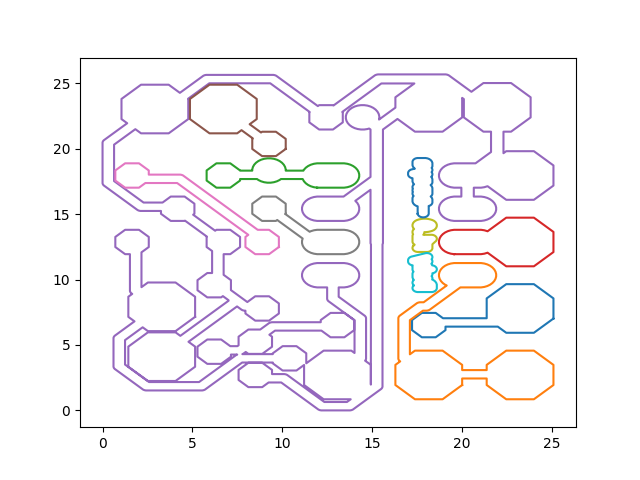

input g-code with outlines at a random spot X,Y

we then move the g-code to 0,0

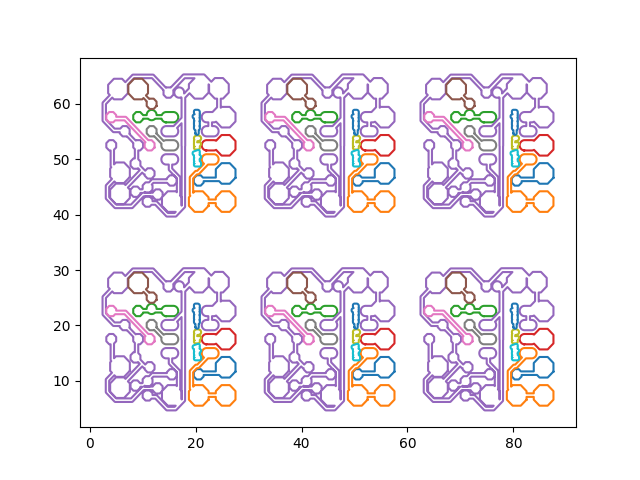

then we nest it as many times as possible

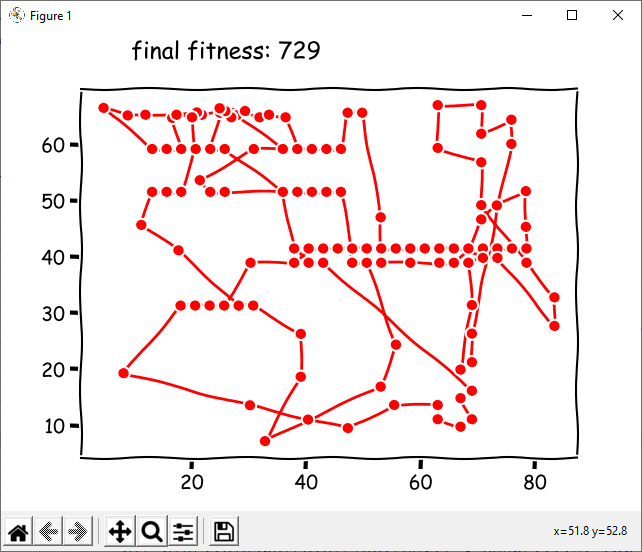

take gcode and do a poor job trying to optimize it

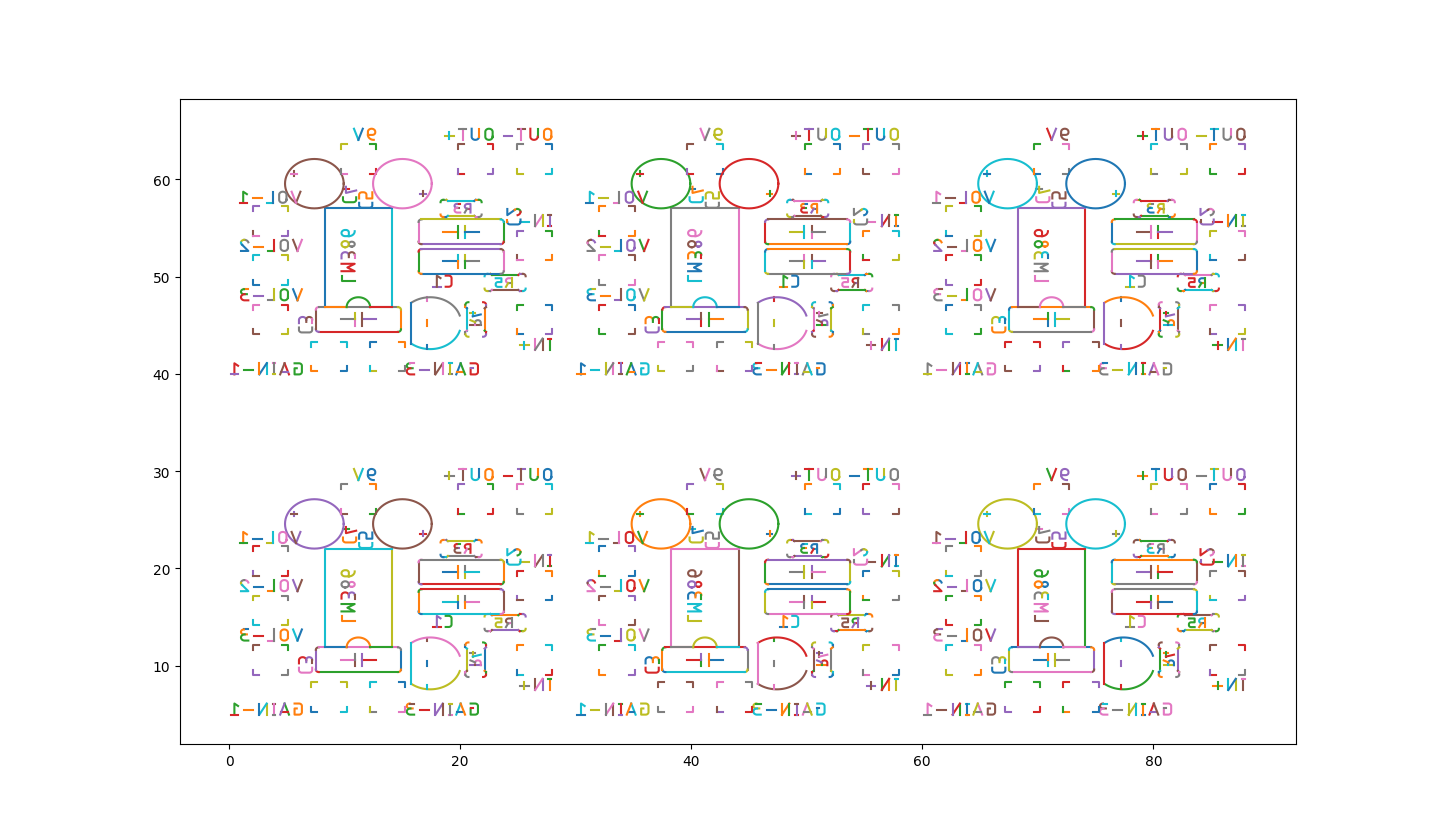

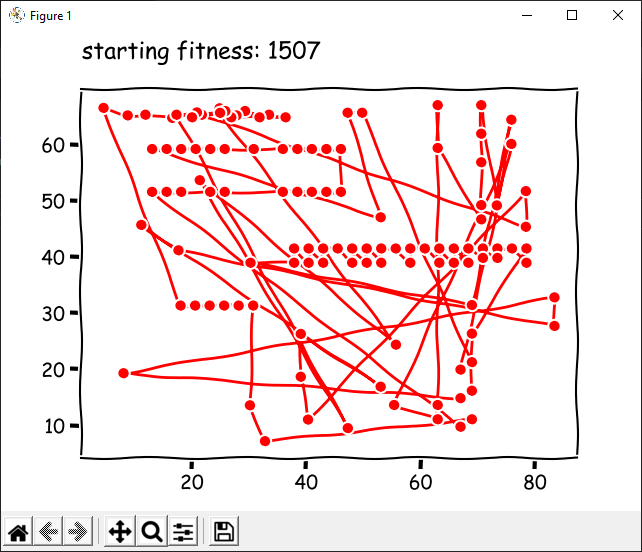

The gcode that we start with looks something like this

After running this crappy code it looks something like this

in eagle

run ULP 'pcb-gcode-setup' to get bottom etch and drill files

file > 'generate CAM data' (cam data is used in flamcam in next step)

in flatcam

'open_gerber <top-silkscreen-file.cam> -follow 1 -outname GTO_follow'

'follow GTO_follow -outname silk_geo'

'cncjob silk_geo'

'write_gcode silk_geo_cnc silk.gcode'

in notepad

edit silk.gcode from flatcam

remove headers/footers

find and replace (include trailing/leading spaces as indicated):

'Y' -> ' Y'

'\n' -> '\nN0 '

'G01 Z-0.0020' -> 'M03'

'G00 Z0.1000' -> 'M05'

in gcodestuff

run and select the 3 files we created above